| View previous topic :: View next topic |

| Author |

Message |

harley guy

Novice

Joined: 25 Nov 2005

Posts: 71

|

Posted: Tue Jul 25, 2006 7:34 pm Post subject: finally done,steel production vac table Posted: Tue Jul 25, 2006 7:34 pm Post subject: finally done,steel production vac table |

|

|

ok first thing.i have to say thanks to all of you on this forum.if it wasnt for you i wouldnt have been able to do it without you all.so thanks.ok i made a over under fully production vac table.everything on my table i made from scartch,even the tank.this table uses air cylinders to raise and lower my cage to the mold and oven (iam lazy).here are some pics of it.when i get some time ill post how to make it.here are some pics.my forming plate only has 1 hole,but thats all i need for what i make.i would show you my pulls but i cant.still waiting for my patent to finish going threw.this is how i make my living.but it works awesome.well here is the pics.hope it will help you with ideas or something.because all you have helped me out with the table.and if you have any questions on welding or fabrication email me.ive been a prototype fabricator for 16yrs.i made my oven with a 5 point wiring system.and the trick to a over under design is installing your top oven,so it forces the heat down,and make your shroud long so your cage goes up inside your shroud to your oven.so here are some pics,hope they help.iam in process of making a flip top design too.well thanks again.this site is awesome

[img]

[/img]

[img]

[/img]

[img]

[/img]

Last edited by harley guy on Fri May 11, 2007 10:34 pm; edited 4 times in total |

|

| Back to top |

|

|

harley guy

Novice

Joined: 25 Nov 2005

Posts: 71

|

Posted: Tue Jul 25, 2006 7:59 pm Post subject: Posted: Tue Jul 25, 2006 7:59 pm Post subject: |

|

|

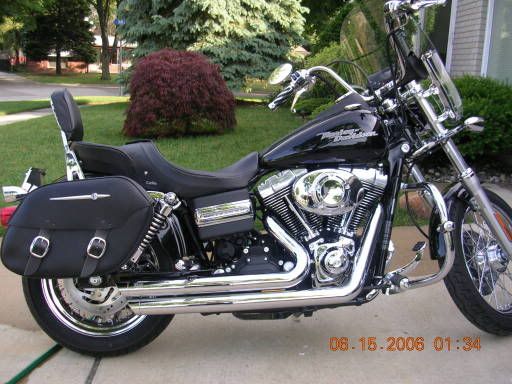

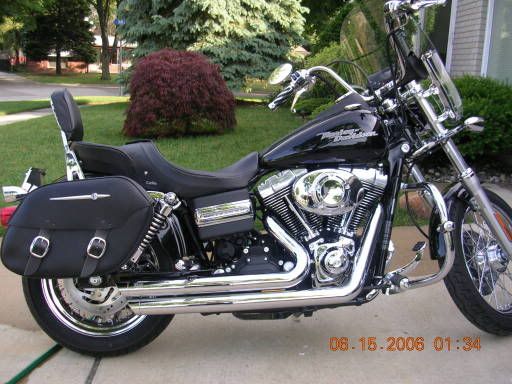

quick answers that you might have questions on.(1)the installtion is betwwen the oven and the shroud.my oven base is recessed 3 inches,then the shroud covers it.(2)the allen bolts you see on my cage are for holding the plastic.i drilled holes all the way threw the top frame of the cage,then welding nuts on the top part of the frame,and screwed in allen bolts in the nuts.so that the other side the bolts sticks out 1/16 of a inch.so when you clamp the frame down to your plastic,the bolts will dig into the plastic and hold it firmly.it will keepyou from wasting any pulls from your plastic pulling out from your cage.works great havnt wasted none in almost 100 pulls.(3)air cylinders i bought from mc master carr.costed 75.00 a piece.you need 2.the air release value is 40.00.and connecters range from 2.00-10.00 a piece(need 6).the hose is cheap you need about 12 feet.(4)installation,i bought it from infaredheaters.com or something like that.were everyone buys thier nico wire from.its cheap they sell it by the sq. foot.(5)vac pump is a j&b 10cfm ,won it on ebay 200.00.(6)tank size is 24x24x12. (note 1 sq. foot =7.8 gallons)so its a 31.2 gallon tank.iam going to make a bigger one,when i gett a couple hrs of free time.(7)the wood i used for my top and my forming plate.are from workbench table tops,i cut down.well thats about all the question i can see from the pics that i think you will ask.i run it off a 30 amp fuse to.well if you have any question ill try to answer.but iam very busy all the time.with work and bussiness.but ill try and help.i will post one day a step by step how to make it.when i get the time.i have all the pics for the post .i think 40 pics total.so it will be some time for a brief how to guide to be posted.but i wanted to get at least this up so at least you can get some ideas.well enjoy.and thanks to all you and the forum for your help to.the profit i have made from this table so far has bought my baby for me(here is a pic of it).so if you make a good table and idea,you can make great money . [img] [/img] [/img]  |

|

| Back to top |

|

|

jegner

Site Admin

Joined: 30 May 2003

Posts: 2144

Location: Texas, USA

|

Posted: Tue Jul 25, 2006 8:58 pm Post subject: Posted: Tue Jul 25, 2006 8:58 pm Post subject: |

|

|

Awesome!

I can't wait to see your build tutorial! Nice job on the tank! And that auto lowering pistons, well, thats just too cool! I can't wait to see some pulls from it!

Thanks for sharing!

Jim

BTW, I'm glad you found this site helpful. |

|

| Back to top |

|

|

AlterEgos

Expert

Joined: 30 May 2006

Posts: 115

Location: Centreville, VA

|

Posted: Wed Jul 26, 2006 12:22 pm Post subject: Posted: Wed Jul 26, 2006 12:22 pm Post subject: |

|

|

I have to echo Jim on this one, that is one fine piece of machinery! And I also look forward to the details on how you did it, very intriguing!!!

_________________

-John |

|

| Back to top |

|

|

crashmann

Guru

Joined: 27 Sep 2005

Posts: 501

|

Posted: Wed Jul 26, 2006 2:37 pm Post subject: Posted: Wed Jul 26, 2006 2:37 pm Post subject: |

|

|

Holy cow, it must be "over-under" season! First Blind Squirrel, now Harley-guy, and my little Sunbeam.

Remarkable work on your oven Harley-guy! The pneumatic pistons truly make it industrial, plus, you don't need locks to hold the plastic frame in position inside the oven. That's great! Plus, thanks for the recommendation on raising the plastic inside the oven shroud. Definitely makes sense.

Hmm, I think I recognize that pattern for the ceramic donuts in your oven

So, what drives the pneumatic pistons?

Charlie

TI-386 |

|

| Back to top |

|

|

harley guy

Novice

Joined: 25 Nov 2005

Posts: 71

|

Posted: Wed Jul 26, 2006 3:10 pm Post subject: Posted: Wed Jul 26, 2006 3:10 pm Post subject: |

|

|

| Quote: | | Hmm, I think I recognize that pattern for the ceramic donuts in your oven Razz ........ |

thats why i had to share my machine with everyone and say thanks to all and the forum.this machine has a little bit of everyone's ideas. thats why i had to share my machine with everyone and say thanks to all and the forum.this machine has a little bit of everyone's ideas.  .if it wasnt for all of you,i would of had to pay $17,000 for a industrail forming machine.then while i was searching for a machine to buy.i ran across this site,and said hmmmmm.looked at all of your guys great ideas,and look at the idustrail ones and said screw that i can make one.and this is what i have come up with. .if it wasnt for all of you,i would of had to pay $17,000 for a industrail forming machine.then while i was searching for a machine to buy.i ran across this site,and said hmmmmm.looked at all of your guys great ideas,and look at the idustrail ones and said screw that i can make one.and this is what i have come up with.  |

|

| Back to top |

|

|

harley guy

Novice

Joined: 25 Nov 2005

Posts: 71

|

Posted: Wed Jul 26, 2006 3:12 pm Post subject: Posted: Wed Jul 26, 2006 3:12 pm Post subject: |

|

|

| Quote: | | So, what drives the pneumatic pistons? |

i use my air compressor,and use a air release value,to raise and lower it.if you notice the lever on the left side of the machine.the air hose connects to that.my computer crashed at home,so cant post pic until i get home and fix it.iam at work right now.ill post pics later.so u can get a better idea |

|

| Back to top |

|

|

Stomper

Master

Joined: 01 Oct 2005

Posts: 473

Location: Woodburn, Oregon USA

|

Posted: Wed Aug 09, 2006 4:50 pm Post subject: Posted: Wed Aug 09, 2006 4:50 pm Post subject: |

|

|

WOWSERS!!! I'm still in the conceptual process for building my vac-table and I'm REALLY digging the over/under thing. I can do all of thing things required to build this table as well, and I LOVE the idea of saving floor space, plus those FAR-OUT Pnuematic cyliders!!!!!! HMmmm........  Can you tell me what model cylinders you are using? I can't seem to find anything on McMaster-Carr.com with over a 12" stroke.... Can you tell me what model cylinders you are using? I can't seem to find anything on McMaster-Carr.com with over a 12" stroke....

_________________

Tony Krewson

FEAR... is not my god!! |

|

| Back to top |

|

|

crashmann

Guru

Joined: 27 Sep 2005

Posts: 501

|

Posted: Thu Aug 10, 2006 7:43 am Post subject: Posted: Thu Aug 10, 2006 7:43 am Post subject: |

|

|

Heh-heh! Heh-heh! He said "12 inch stroke!"

Heh-heh! Heh-heh!

Charlie

Butthead-386 |

|

| Back to top |

|

|

Stomper

Master

Joined: 01 Oct 2005

Posts: 473

Location: Woodburn, Oregon USA

|

Posted: Thu Aug 10, 2006 4:13 pm Post subject: Posted: Thu Aug 10, 2006 4:13 pm Post subject: |

|

|

Awww c'mon.... I didn't mention ANYTHING about my 12" personality!

_________________

Tony Krewson

FEAR... is not my god!! |

|

| Back to top |

|

|

harley guy

Novice

Joined: 25 Nov 2005

Posts: 71

|

Posted: Thu Aug 10, 2006 8:38 pm Post subject: Posted: Thu Aug 10, 2006 8:38 pm Post subject: |

|

|

they are bimba air cylinders 27'inch stroke | Quote: | Can you tell me what model cylinders you are using? I can't seem to find anything on McMaster-Carr.com with over a 12" stroke....

_________________

|

|

|

| Back to top |

|

|

crashmann

Guru

Joined: 27 Sep 2005

Posts: 501

|

Posted: Mon Aug 14, 2006 2:42 pm Post subject: Posted: Mon Aug 14, 2006 2:42 pm Post subject: |

|

|

I'm having trouble finding Bimba air cylinders on McMaster, but I did find long stroke air cylinders on page 924. Part number 6471K37 with a 1" bore is available with a 19 to 24" stroke length. That should probably work ok.

What do you think Harley Guy? Is this close to what you are using?

And for valves... Holy cow! There's a ton to choose from! I have no idea which one to pick in that category...

Charlie

TI-386 |

|

| Back to top |

|

|

harley guy

Novice

Joined: 25 Nov 2005

Posts: 71

|

Posted: Wed Aug 16, 2006 8:06 pm Post subject: Posted: Wed Aug 16, 2006 8:06 pm Post subject: |

|

|

| Quote: | I'm having trouble finding Bimba air cylinders on McMaster, but I did find long stroke air cylinders on page 924. Part number 6471K37 with a 1" bore is available with a 19 to 24" stroke length. That should probably work ok.

What do you think Harley Guy? Is this close to what you are using?

And for valves... Holy cow! There's a ton to choose from! I have no idea which one to pick in that category...

|

sorry for not replying sooner,just got back from vacation.i have to check out the specs on them for you first.you have to be very careful on cyclinders and regulators.can be very dangerous if you havnt used them before or pick the wrong equipment.ill let you know if they will work.but i have been thinking of redesigning a new machine.but not sure if i have enough steel for a new one.but if i do.ill be selling my air cylinders and regulator and adapters.if your interested.but give me a couple days to make some drawings up and get some measurements.so i can see if i can build another one.but i cant check those one cyclinders out until monday when i get back to work.so give me a few days to check them out and do some designing. |

|

| Back to top |

|

|

Mattax

Expert

Joined: 09 Mar 2006

Posts: 160

Location: Virginia

|

Posted: Wed Sep 27, 2006 1:42 am Post subject: Posted: Wed Sep 27, 2006 1:42 am Post subject: |

|

|

| harley guy wrote: | | (3)air cylinders i bought from mc master carr.costed 75.00 a piece.you need 2.the air release value is 40.00.and connecters range from 2.00-10.00 a piece(need 6).the hose is cheap you need about 12 feet. |

I am looking over McMaster Carr and I cannot find the cylinders you have in the pics. Let me know which ones they are and also the mounting brackets.

Thanks.

_________________

Mattax

TK487

Garrison Tyranus |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Thu Sep 28, 2006 9:05 am Post subject: sunbeam? Posted: Thu Sep 28, 2006 9:05 am Post subject: sunbeam? |

|

|

Charlie,

Anything to report about your little Sunbeam over-and-under?

I managed to get my hands on a little Sunbeam grill---which they don't seem to sell new anymore---and I'd like to make a little over-and-under, too.

Looking at it, it seems like the heating element is not not nearly big enough to heat an 18 x 12 sheet of plastic evenly, without serious tweaking of reflectors and some screening. As Jim said in his little article, 2 of those elements would be better. (So that the heating elements go past the edge of the plastic, rather than stopping short of the edge.)

This makes me think that Ralis Kahn's over-and-under design can't really work the way it should. He is probably not getting a good seal around the corners of his upside-down-cookie-sheet platen.

I'd guess it works pretty well with a shop vac anyway, because the shop vac can deal with a fair bit of leakage around the edges of a small platen. For a low-volume high-vacuum system, though, I'd think it'd be a serious problem.

Paul |

|

| Back to top |

|

|

|

[/img]

[/img]