|

www.TK560.com

Vacuum Forming, Movie Prop, Sci-fi and GIjOE Forum

|

|

|

| View previous topic :: View next topic |

| Author |

Message |

ahillworks

Master

Joined: 18 Nov 2007

Posts: 308

Location: Orlando FL

|

Posted: Sun Sep 21, 2008 10:14 am Post subject: Posted: Sun Sep 21, 2008 10:14 am Post subject: |

|

|

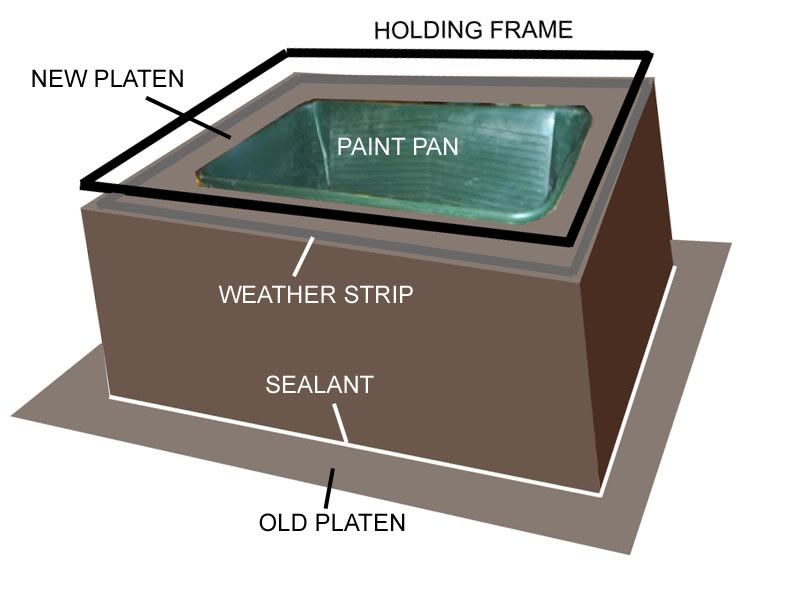

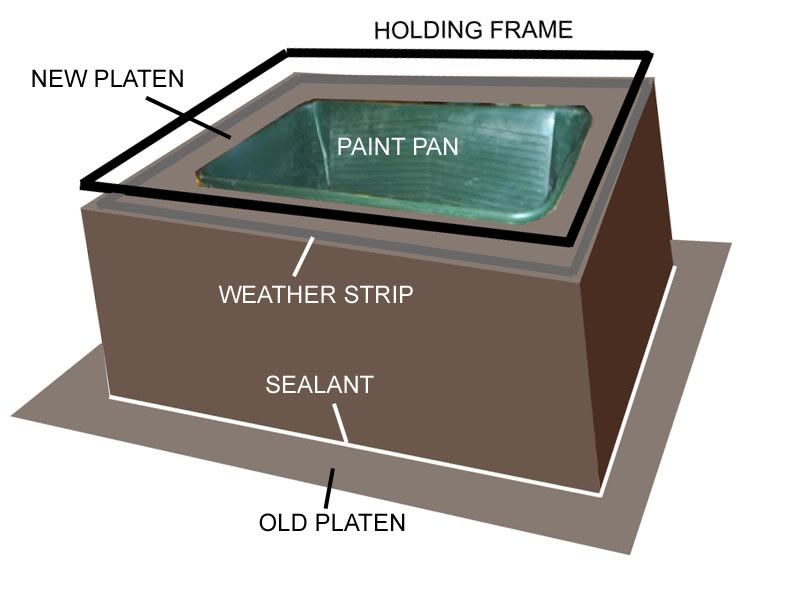

| ANH trooper wrote: | You could try making your negative mould like this....

By making a wooden box that is about 1" taller than your paint pan and cutting out the top panel slightly smaller than the edge lip so the pan can sit in the box, you should get good results.

Put the weather strip on top as shown, and just use this as your new platen. It might be a bit tricky to load up your plastic though? Make sure to drill small holes on the bottom edges of the pan to draw the plastic down. |

Great design the only thing I would do differ is let the plastic go over the edges like you would with a normal platen. This will ensure a better seal. Just my 2 cents lol. Also on the inside make sure you seal the walls of the wood with like paint or a sealer. This will prevent air from trying to seep threw the wood it self. :::OR:::

You could take the paint pan and raise like 6 inches up and place it in a wood box and make a good plaster mold and then just seal that to the platen and would be air tight no matter what because the seal is only on the bottom =) Just on the bottom cut out where the hole would be and seal away placing like a 25 or 50 pound weight on top to make sure the seal is good and leave it over night to settle.

Just some thoughts lol |

|

| Back to top |

|

|

cod

Master

Joined: 05 Nov 2006

Posts: 322

Location: San Francisco

|

Posted: Mon Sep 22, 2008 6:19 am Post subject: Posted: Mon Sep 22, 2008 6:19 am Post subject: |

|

|

You might want to consider a 'plug-assist' tool as well. this would be another tool, covered with felt, that would be used to forcibly push the plastic down into(or on) your mold. I've only read about this being used in industrial thermoforming, but it does seem like it would help with such a deep draw. It basically would be you doing some of the work in stretching the plastic by hand, with a piece of felt-covered wood or something that you could ring around the outside of a positive mold (or push into the cavity of a negative mold.)

It may be though that a shop vac system will never be strong enough to make this technique viable.

just more thoughts to muddy your brain

_________________

<.o'> |

|

| Back to top |

|

|

inventer

Novice

Joined: 22 Apr 2008

Posts: 55

|

Posted: Tue Sep 23, 2008 2:18 am Post subject: great ideas Posted: Tue Sep 23, 2008 2:18 am Post subject: great ideas |

|

|

Thanks gang, you guys have alot of great ideas and one or all should help. Stopped at Lowes yesterday and bought some wood. This is a fun hobby, (project) and I have fun doing it, but boy it's getting costly, whats the ole saying, you gotta pay to play  I'll try working on this after work this week, if not, I will be working on it this weekend between working on the motor of my show van, thanks again gang, Tony I'll try working on this after work this week, if not, I will be working on it this weekend between working on the motor of my show van, thanks again gang, Tony |

|

| Back to top |

|

|

inventer

Novice

Joined: 22 Apr 2008

Posts: 55

|

Posted: Sat Sep 27, 2008 10:47 am Post subject: you guys rock Posted: Sat Sep 27, 2008 10:47 am Post subject: you guys rock |

|

|

Man, YOU GUYS ROCK, I'm so stinkin happy  , best pulls I've ever made. Did 2 pulls, one with the .010 PETG and one with the .015 PETG, I'm blown away. The .010 pull is pretty thin, but the .015 pull came out great. One of you's said about the PETG plastic stretches like crazy, I've never had and thing stretch like this before, man, you guys ROCK. , best pulls I've ever made. Did 2 pulls, one with the .010 PETG and one with the .015 PETG, I'm blown away. The .010 pull is pretty thin, but the .015 pull came out great. One of you's said about the PETG plastic stretches like crazy, I've never had and thing stretch like this before, man, you guys ROCK.  Bet you can't tell I'm happy ? Bet you can't tell I'm happy ?  No webbing at all, none, nada, none at all, WOW, I'm so happy. Heres some pics I took, No webbing at all, none, nada, none at all, WOW, I'm so happy. Heres some pics I took,

http://smg.photobucket.com/albums/v81/vanner40/inverted%20pulls/

Now I need to do some modifications to the mold, after that I'll be pulling away, guess what I'm doing sunday ???  Whooooo, hooooo, you guys are awsome, thank you so very much, I do get frustated at times, but I've never been a quitter, yet. I'll keep you posted after tomorrows pulls. Tony Whooooo, hooooo, you guys are awsome, thank you so very much, I do get frustated at times, but I've never been a quitter, yet. I'll keep you posted after tomorrows pulls. Tony |

|

| Back to top |

|

|

CrazyFool

Expert

Joined: 07 May 2008

Posts: 203

|

Posted: Sat Sep 27, 2008 12:49 pm Post subject: Posted: Sat Sep 27, 2008 12:49 pm Post subject: |

|

|

| Right on inventor! Great photos. Looks like you have a winner now! |

|

| Back to top |

|

|

ahillworks

Master

Joined: 18 Nov 2007

Posts: 308

Location: Orlando FL

|

Posted: Tue Sep 30, 2008 1:19 pm Post subject: Posted: Tue Sep 30, 2008 1:19 pm Post subject: |

|

|

| I told you it streches lol Cool glad you got it to work. Hey I want to see a video of this working this looks kinda cool. Been thinging about doing this and just may start now with some things I want to make. |

|

| Back to top |

|

|

ahillworks

Master

Joined: 18 Nov 2007

Posts: 308

Location: Orlando FL

|

Posted: Tue Sep 30, 2008 1:23 pm Post subject: Posted: Tue Sep 30, 2008 1:23 pm Post subject: |

|

|

| Ok so like did you place a hole at the bottum of this?? I really like to know how it worked. lol. I see you also go the lip and all the ripples. Man I really need to know how this worked. lmao. |

|

| Back to top |

|

|

inventer

Novice

Joined: 22 Apr 2008

Posts: 55

|

Posted: Wed Oct 01, 2008 12:55 am Post subject: video Posted: Wed Oct 01, 2008 12:55 am Post subject: video |

|

|

| Thanks guys, I did some more pulls on sunday, but did'nt want to waste anymore plastic. I've been working on the mold, adding my trademark. I'll do a video this weekend when I ready to make my show samples to put out in the stores. I knew PETG stretched, but not as good as it does for the inverted pulls. |

|

| Back to top |

|

|

ahillworks

Master

Joined: 18 Nov 2007

Posts: 308

Location: Orlando FL

|

Posted: Wed Oct 01, 2008 2:33 pm Post subject: Posted: Wed Oct 01, 2008 2:33 pm Post subject: |

|

|

| Cool can not wait to see this. Yeah kinda cool when it does that. First time I got it to work it streched over my mold I was like WAAA wait a minute lol. Its cool though. |

|

| Back to top |

|

|

inventer

Novice

Joined: 22 Apr 2008

Posts: 55

|

Posted: Sat Oct 04, 2008 1:45 pm Post subject: video Posted: Sat Oct 04, 2008 1:45 pm Post subject: video |

|

|

Hi gang, you'll have to excuse me on the video, I woke up sick yesterday, guess I over did it working and ran myself down, just painted a 7000 sq ft store with 5 colors in 8 days. I drug myself out to the garage to make you's this video and my sweetie helped. The videos loaded backwards, video 2,1 instead of video 1,2. I'll never be a movie producer  Well let me know what you think, heading back to the couch, I gotta try and shake this before work monday. Tony Well let me know what you think, heading back to the couch, I gotta try and shake this before work monday. Tony

http://smg.photobucket.com/albums/v81/vanner40/inverted%20pull%20tk560%20fourm/ |

|

| Back to top |

|

|

CrazyFool

Expert

Joined: 07 May 2008

Posts: 203

|

Posted: Sat Oct 04, 2008 1:58 pm Post subject: Posted: Sat Oct 04, 2008 1:58 pm Post subject: |

|

|

OUTSTANDING!!!    You did it buddy! Whooo hoooo!!! You did it buddy! Whooo hoooo!!! |

|

| Back to top |

|

|

jegner

Site Admin

Joined: 30 May 2003

Posts: 2144

Location: Texas, USA

|

Posted: Sat Oct 04, 2008 6:58 pm Post subject: Posted: Sat Oct 04, 2008 6:58 pm Post subject: |

|

|

All right! Man, your in business now! I hope you can sell a ton of these!

Jim |

|

| Back to top |

|

|

ahillworks

Master

Joined: 18 Nov 2007

Posts: 308

Location: Orlando FL

|

Posted: Sun Oct 05, 2008 12:15 pm Post subject: Posted: Sun Oct 05, 2008 12:15 pm Post subject: |

|

|

Wow man that is cool. I have a question though. Is the mold raised and has two holes in the bottom? I am trying to figure out how you get the lips to pull on the edges.. I want to make some molds of some project but need to be sure I do it right. If it is raised then the whole box is being vacuumed out correct?

I know so many questions sorry. But man I watched that video like 20 times lol that was the coolest thing to watch this get pulled in reverse lol. |

|

| Back to top |

|

|

inventer

Novice

Joined: 22 Apr 2008

Posts: 55

|

Posted: Mon Oct 06, 2008 1:36 am Post subject: thanks guys Posted: Mon Oct 06, 2008 1:36 am Post subject: thanks guys |

|

|

| Ahill, the mold is just sitting on the vac table top, theirs holes in the vac table, drilled several holes in the mold bottom just like they suggested on here, now I did screw the mold to the table so it don't move around. The mold is level with the wood box around it, theirs a 1/8" gap between the mold and wood top, thats how the lip gets so perfect. After all the other ways I've been trying, this one just blew me away. What I'd like to do now is figure out a way to make my oven with the nichrome wire and do away with the 2-220 lines. If you want to see more pic's of the box, table, mold or something, let me know, I'll do my best to take some. Thanks again guys. I see theirs alot of new guys posting on here, I hope they learn alot like I did from you guys. Tony |

|

| Back to top |

|

|

spektr

Master

Joined: 07 Jan 2008

Posts: 425

|

Posted: Mon Oct 06, 2008 12:10 pm Post subject: Why Weatherstripping? Posted: Mon Oct 06, 2008 12:10 pm Post subject: Why Weatherstripping? |

|

|

I see weatherstripping listed in the drawing. If you use silicone sealant, real silicone sealant, not latex crap, it wont ever melt, AND you dont have to keep messing with it every part. On molds where you use wood and need to seal things, use silicone seal and squeegee it around. It lasts for hundreds of pulls, is cheap, smearable and really effective...

Scott. |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|