|

www.TK560.com

Vacuum Forming, Movie Prop, Sci-fi and GIjOE Forum

|

|

|

| View previous topic :: View next topic |

| Author |

Message |

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Tue Feb 09, 2010 4:45 pm Post subject: rebuild my machine i need help Posted: Tue Feb 09, 2010 4:45 pm Post subject: rebuild my machine i need help |

|

|

hello there!!

has some time since I wrote in the forum and see that there is much new information, I'm trying to read everything, but it's lot of information hehe  , thanks for sharing your knowledge , thanks for sharing your knowledge

i was make a machine Based a flip-flop design of the page jim (I'm very grateful for all the information that he shares) with small changes such as the oven is made from propane instead of electric

I am very happy with the performance of the machine but seeing some post, I realized that there is a very nice design where the oven is in the top, this helps a lot when you do not have ample work space, so I've decided try it, basically my goal is change the oven to the top, change the shop vac for a vacuum pump and add the handle to lower the holding frame

before starting rebuild the machine, I have some questions, I would like to reuse some parts from my old machine but not how is it possible for example the oven

as i say it is powered by propane burners, i like to know what possibility exists that heat is projected downward? because i think the heat usually rises. with the oven below the plastic the heat dont have problem to get the plastic, because heat is received directly, but if it is put above, I am not sure that the heat received by the plastic is sufficient to soften it

there any way to manage the heat generated by the burners?

I am very interested in the a gas oven because where I live, is almost impossible to get the electric elements

I would also like to know if I can reuse the suction surface?, which I have, has many holes, in your experience this system has better performance or is it better a single hole in the center?

on the other hand, am about to buy a vacuum pump with these specifications:

CENTURY AC MOTOR

3 / 4 HP

TYPE CS

115/230 VOLTS

Hz 60

1725 RPM

26 "HG

MOD TA-0100-V

the pictures may be help to know if these vacuum pump works for thermoforming

I wonder if it works, before purchasing thanks for your answers |

|

| Back to top |

|

|

jdougn

Guru

Joined: 18 Mar 2009

Posts: 714

Location: Louisville KY area

|

Posted: Wed Feb 10, 2010 7:58 am Post subject: Posted: Wed Feb 10, 2010 7:58 am Post subject: |

|

|

Hey Israel, good to see you post up again!

I don't have any experience with the propane burners but I might be able to offer some help on the pump. The one detail that I didn't see listed was "Cubic Feet per Minute" so I looked up the model number on the internet to find this may be a very nice, 10 CFM pump made by RIETSCHLE THOMAS.

http://www.gd-thomas.com/product.aspx?id=14600&tp=v

Of course it will be important to make sure the electrical motor and the rotary vane vacuum pump are both working properly. Let the pump run long enough to create maximum vacuum in the attached tank. At 10CFM it should only take a minute or so for the pump to reach maximum vacuum and it should probably shut itself off at that point. Turn off the pump and let it set to see if it holds vacuum. I can't see a vacuum gauge on the tank but if there is a gauge, make sure that the vacuum gauge reads close to 26inHg. (This number will vary depending upon your exact geographical elevation.)

Listen to the system run. It should sound nice and smooth with no rough noises. On the worn out vacuum pumps I've listened to they sound like they have small stones inside the pump. Also, the electric motor should start quickly and run smoothly. One indicator of a bad electric motor is that it will have a harsh burnt smell.

It will probably be okay to reuse your platen (suction surface). Try it to see if it works then make changes. I use a single vacuum hole on my 2'x4' platens and they work just fine.

If this pump is in good condition it is great for vacuum forming. Hope it works out for you!

Hope this helps,

DougN

_________________

DougN - Just in case you're wondering, I got my "rating" legitimately... by posting aimless drivel, useless advice, and pointless questions. |

|

| Back to top |

|

|

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Wed Feb 10, 2010 12:51 pm Post subject: Posted: Wed Feb 10, 2010 12:51 pm Post subject: |

|

|

hi Doug, i will check the pump, the seller says it is in perfect condition but it is worth reviewing the price I think, that is fine (4000 pesos approximately 306 USD), a question more about the pump, will need to add an extra tank? the machine will measure 2 'x 2'

so i will prove the platen but what I want is to get the best possible detail in Styrene .100- .125, I have been reading the forum and found different opinions but most I've read, agree that a single hole is better

thank you very much for the advice and assistance |

|

| Back to top |

|

|

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Sat Feb 20, 2010 12:24 am Post subject: Posted: Sat Feb 20, 2010 12:24 am Post subject: |

|

|

hello on the vacuum pump, in fact, is 10 CFM pump made by RIETSCHLE THOMAS

http://www.gd-thomas.com/product.aspx?id=14600&tp=v

I already have the vacuum pump, but I have no idea how it works, unfortunately, has no user manual, need your help

I wonder if only when connected to a power source, it starts sucking air like a vacuum cleaner or do I have to wait some time?

I wonder which is what I do to see if it actually works, the engine makes some noise, but that has not noticed any suction, only through the holes in the side that blows air feels

I wonder also for what are the two deposits,are filters or oil container? and where is the exits and enters the air because it has a valve (as crank) which get two hoses, but neither feels suction even for rotation valve

could be that no matter the engine running, the pump is not working? I'm doing something wrong?

I hope you can help me as soon as possible because it does not work to tell the seller thanks |

|

| Back to top |

|

|

jdougn

Guru

Joined: 18 Mar 2009

Posts: 714

Location: Louisville KY area

|

Posted: Sat Feb 20, 2010 8:35 am Post subject: Posted: Sat Feb 20, 2010 8:35 am Post subject: |

|

|

Hello Israel,

The pump does not move a lot of air like a vacuum cleaner. It moves a relatively small amount of air but it creates a much deeper vacuum than a vacuum cleaner. The two glass jars important since they are filters. One is designed to keep dust out of the pump.

We need to know which way the pump is moving the air before your pump can be tested. Where do you feel the air blowing out? Do you feel air blowing out of one of the glass jars on the pump?

Or, do you feel air blowing out of the hoses on the tank?

Also look at the top of the pump where the pipes come out to the glass jars. There may be small arrows that indicate the direction that the air is moving. We need to know this information first.

DougN

_________________

DougN - Just in case you're wondering, I got my "rating" legitimately... by posting aimless drivel, useless advice, and pointless questions. |

|

| Back to top |

|

|

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Sat Feb 20, 2010 10:03 am Post subject: Posted: Sat Feb 20, 2010 10:03 am Post subject: |

|

|

hello DougN, thanks for all the help

the air blows out, only from small holes on the side of the pump, one of the jars is connected to the tank, perhaps by blowing air there, but is connected to the tank and I can not know, should i disconnect it to make sure?

hoses from the tank, not blowing anything either sucks

top of the jars no arrows showing where you move the air, there is only a large label that says, "rotation" may be this helps

alse there are a valve and another thing i dont know what is for

I wonder if the jars have to go empty or i have to put them something in them, like water or oil? there is a label that says:

"warning

max. 5lbs psi

remove jar before

starting 3 hp motors

to check rotation"

could be that the engine runs and does nothing vacuum? and that the pump did not really serve? I put some pictures to explain better

thanks again |

|

| Back to top |

|

|

jdougn

Guru

Joined: 18 Mar 2009

Posts: 714

Location: Louisville KY area

|

Posted: Sun Feb 21, 2010 2:00 pm Post subject: Posted: Sun Feb 21, 2010 2:00 pm Post subject: |

|

|

Hello Israel,

Thanks for the pictures and explanation. I'm not a pump expert but I think we can do a simple test.

Disconnect the hose from the elbow on the righ side of the pump.

Use a flat piece of thick paper or something similar for this part of the test. (Don't use your hand since deep vacuum could hurt you.) With the pump running, block only one hole with the thick paper and see what the paper does. Then, with the pump still running, check the other hole the same way. Block only one hole at a time.

If the pump is working the thick paper should either be pushed away by air blowing out the hole, or immediately pulled against the hole and held in place by the vacuum. If the thick paper is not held in place by one of the holes then the pump is not working. If the pump is not working the seals that create the vacuum are probably worn out and would have to be replaced which can be expensive.

Let us know your results!

hth, DougN

_________________

DougN - Just in case you're wondering, I got my "rating" legitimately... by posting aimless drivel, useless advice, and pointless questions. |

|

| Back to top |

|

|

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Sun Feb 21, 2010 9:06 pm Post subject: Posted: Sun Feb 21, 2010 9:06 pm Post subject: |

|

|

thanks dougN, bad news....i made the test and no any succtior or blowing out

i search in interntet looking for a owner manual for the vacuum pump and i dont found, but i found the manual for a gast vacuum pump (very similar) a Oilless Rotary Vane Vacuum Pump and in the "TROUBLESHOOTING CHART" i Find exactly what happens to the pump

low vacuum/pressure -------Vanes sticking. Clean or replace. or Vanes worn. Replace. or Shaft seal worn. Replace.

i was hoped that as you said they were the seal then I follow the instructions for disassembly (luckily the bomb had the same parts are marked in the manual) when I remove the end plate, the vanes were broken...

i dont think replace the vanes are complex but i dont know if that's expensive...... now i dont know if return the pump to seller or change the vanes, the problem is that almost no pumps used at a good price (only for refrigeration systems with very low capacity) and new cost very expensive (more than 1,500 dollars excluding the tank... too high for my budget  ) what should I do ) what should I do

on the other hand, I did a test by placing plastic under my gas oven and it works!!!, the plastic was heated even better than above (more faster) the only problem is that the plastic turns a bit yellow, I guess it was because i put very close to the flame, I will try to put some protection to avoid that

but i have to solve de problem with the pump first, before i start make the new vacuum form, I will continue to report... thanks |

|

| Back to top |

|

|

jdougn

Guru

Joined: 18 Mar 2009

Posts: 714

Location: Louisville KY area

|

Posted: Mon Feb 22, 2010 8:36 am Post subject: QR-0100 Posted: Mon Feb 22, 2010 8:36 am Post subject: QR-0100 |

|

|

Wow, too bad the vanes are broken. That would be a nice pump for vacuum forming. The TA-0100 is probably an older version of the QR-0100. I can't find any information on repair parts for either the QR or TA-0100.

Here's some information on the QR-0100

http://www.piisa.com.mx/_Bomba_de_Vacio_de_Paletas_Rotativas_34_HP_115V_10_PCM_1236.htm?sessionid=56675926741207031

Maybe you know about the company listed below. They are a representative for your pump.

Productos Industriales de Importación S.A.

Av. Ruiz Cortines No. 148 Ote.

Colonia Villa San Antonio

Monterrey

CP 67110

Mexico

Tel: +52 (818) 344 5888

Fax: +52 (818) 327 0212

rgparedes@piisa.com.mx

www.piisa.com.mx

_________________

DougN - Just in case you're wondering, I got my "rating" legitimately... by posting aimless drivel, useless advice, and pointless questions. |

|

| Back to top |

|

|

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Mon Feb 22, 2010 12:03 pm Post subject: Posted: Mon Feb 22, 2010 12:03 pm Post subject: |

|

|

thanks again dougN i will contact the company and ask for repair parts

i hope the pump can be repaired, i keep you informed  |

|

| Back to top |

|

|

spektr

Master

Joined: 07 Jan 2008

Posts: 425

|

Posted: Mon Feb 22, 2010 12:27 pm Post subject: Posted: Mon Feb 22, 2010 12:27 pm Post subject: |

|

|

| in many cases the vanes will be free, they hate to have pumps fail that way ... |

|

| Back to top |

|

|

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Mon Feb 22, 2010 1:50 pm Post subject: Posted: Mon Feb 22, 2010 1:50 pm Post subject: |

|

|

i hope so spektr

today i call a company that sells carbon vanes and asked for the number of part....  look at the labels that got the bomb, but says nothing about that (I thought all the vacuum pump blades were equal but not) look at the labels that got the bomb, but says nothing about that (I thought all the vacuum pump blades were equal but not)

also wrote to the company mentioned by dougN, i wait for awnser

i dont know where to get that information, so wrote to Thomas company, I hope they send me the data |

|

| Back to top |

|

|

jegner

Site Admin

Joined: 30 May 2003

Posts: 2144

Location: Texas, USA

|

Posted: Mon Feb 22, 2010 9:55 pm Post subject: Posted: Mon Feb 22, 2010 9:55 pm Post subject: |

|

|

Good to hear from you again! It has been a long time!

For folks that don't know, Israel was the artist that made those fantastic looking CAD drawings of the stormtrooper armor. |

|

| Back to top |

|

|

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Tue Feb 23, 2010 1:08 pm Post subject: Posted: Tue Feb 23, 2010 1:08 pm Post subject: |

|

|

Hi Jim, yes has spent some time since I entered the forums, but a few days ago i come back and I realized there are lots of new information, (i am still reading) so I have decided to rebuild my machine, and change to the high vacuum system, you folks are my inspiration

I am happy to greet you, my friend! I am sure with the advice of all in here i can rebuild the machine successfully |

|

| Back to top |

|

|

Israel franco

Novice

Joined: 22 Sep 2005

Posts: 51

Location: mexico d.f.

|

Posted: Mon Mar 01, 2010 12:48 pm Post subject: Posted: Mon Mar 01, 2010 12:48 pm Post subject: |

|

|

good news, I found a supplier of carbon vanes, I am waiting to arrive

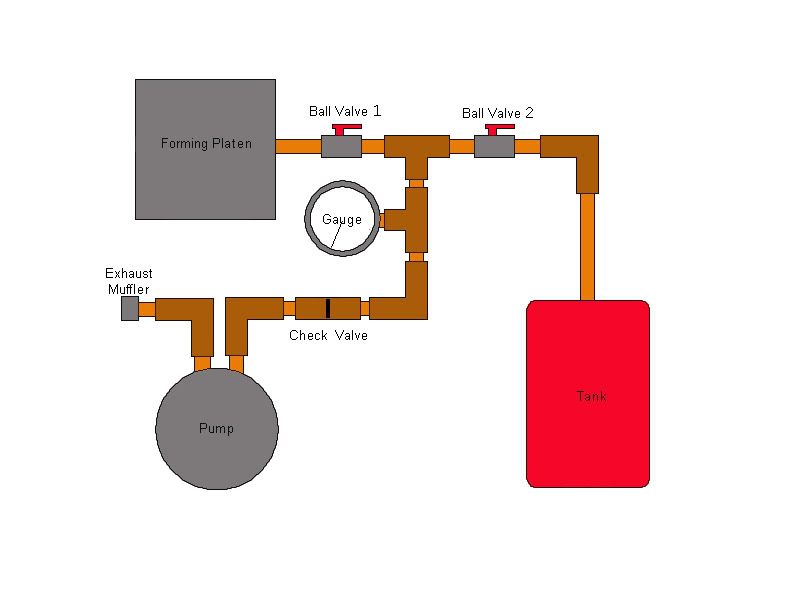

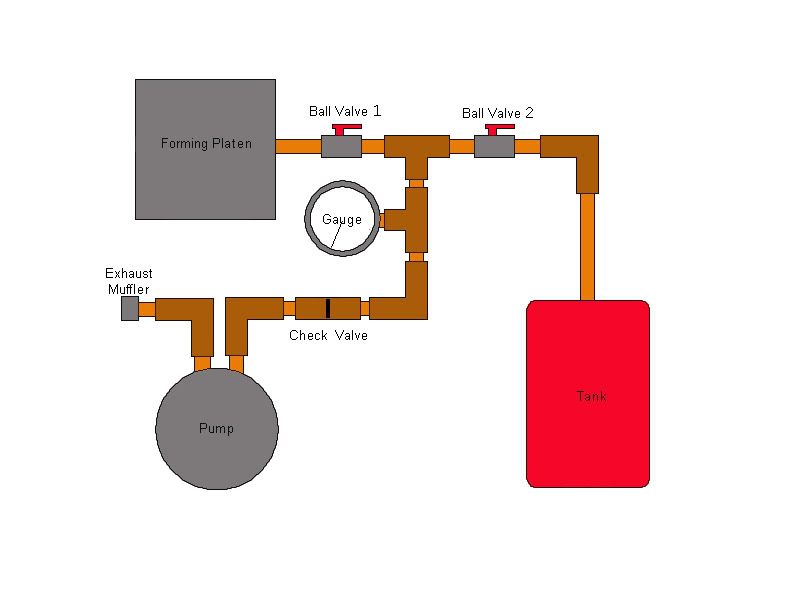

in the meantime i would like to know which system of plumbing i have to use to optimally perform

I've been reading about the two stage vacuum:

http://cnczone.com/forums/showthread.php?t=38493 (thanks drcrash for share)

and I realized that there are many ways to connect the pipe, according to the capacity of the vacuum pump, which you think would be the way most convenient?

tank size will be sufficient (according to the photos of the vacuum pump) or need to get another tank (its a 2x2 vacuum table)

this can work to me?:

the image from this post http://www.tk560.com/phpBB2/viewtopic.php?t=880&postdays=0&postorder=asc&start=15

thanks |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|