| View previous topic :: View next topic |

| Author |

Message |

tallpaul

Newbie

Joined: 31 Oct 2006

Posts: 10

Location: Middletown NY

|

Posted: Thu Nov 02, 2006 5:44 pm Post subject: Glad I found this place! Posted: Thu Nov 02, 2006 5:44 pm Post subject: Glad I found this place! |

|

|

Hi guys,

First I would like to thank Dr Crash for posting this site on Hobby Molding.

There sure is ALOT more going on here!

I built a Hobby-Vac machine about 4 years ago. It works great but it has it's limitations. I need to build a larger over/under to make some RC car bodies.

Here's some photos of my work so far.

|

|

| Back to top |

|

|

dman

Novice

Joined: 09 Oct 2006

Posts: 34

|

Posted: Thu Nov 02, 2006 5:58 pm Post subject: Posted: Thu Nov 02, 2006 5:58 pm Post subject: |

|

|

I'm not sure that I'm the best to say welcome aboard since I'm pretty new here too but I'll say it anyway, welcome aboard.

That's a helluva good looking machine you have there and you do nice work. |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Thu Nov 02, 2006 9:30 pm Post subject: Posted: Thu Nov 02, 2006 9:30 pm Post subject: |

|

|

| Quote: | | That's a helluva good looking machine you have there and you do nice work. |

Yeah, both. Nice, nice.

A couple of questions about Hobby-Vac...

How does that swing frame work? It's adjustable, right? The sidebars move in and out, so that you can use different-sized clamping frames... ?

Also, what kind of check valve do you use? My impression is that Walsh recommends a regular white spring-loaded-disk PVC check valve in his plans. (His book talks about a black sump pump valve, which is a swing valve, plus a rubber band. I've done that, but I'm not thrilled with it.)

More pictures would be great. Experience reports, too.

Not-Tall Paul

Last edited by drcrash on Sat Nov 04, 2006 10:42 am; edited 1 time in total |

|

| Back to top |

|

|

tallpaul

Newbie

Joined: 31 Oct 2006

Posts: 10

Location: Middletown NY

|

Posted: Fri Nov 03, 2006 4:45 am Post subject: Posted: Fri Nov 03, 2006 4:45 am Post subject: |

|

|

Thanks for the compliments.

The swing frame is a set size. The plans are for a 12" x 18" frame and platen but I modified it to 12" x 16" to make better use of an 8' x 4' sheet of Lexan. The plans do show how to make spreader bars for different sizes.

I didn't install a check valve for a 2 stage system. I have a Robinair 10 cfm rotary vane pump directly below the platen.

Let me know what you want to see and I'll take some pics.

Paul |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Fri Nov 03, 2006 7:09 am Post subject: Posted: Fri Nov 03, 2006 7:09 am Post subject: |

|

|

| Quote: | The swing frame is a set size. The plans are for a 12" x 18" frame and platen but I modified it to 12" x 16" to make better use of an 8' x 4' sheet of Lexan. The plans do show how to make spreader bars for different sizes.

I didn't install a check valve for a 2 stage system. I have a Robinair 10 cfm rotary vane pump directly below the platen. |

I guess I was mostly interested in the plumbing and the adjustable frame, but I'm interested in all aspects of vacuum former designs.

Hobby-Vac seems to have unusually rounded corners. I'm wondering if that's so it can get a good seal if the very corners aren't hot and soft enough to form very well. (Maybe just for really thick plastic.) Or maybe it's so that really thin plastic is less likely to tear if it's really soft and you suck it down really hard.

Do you know how much leakage you're getting around the edge of the platen? Does your 10 CFM pump keep up easily?

(Is the white cylinder off to the left your surge tank, or just your water heater? If it's a surge tank, does the vac gauge keep dropping after the plastic is sucked down, or does it stabilize or even go up?)

| Code: |

Let me know what you want to see and I'll take some pics. |

Close-ups of the oven and the insides would be interesting.

The nichrome coil is wired directly to the "ceramic fiberboard," without any little ceramic insulators, right? Do you know what kind of board it is? |

|

| Back to top |

|

|

tallpaul

Newbie

Joined: 31 Oct 2006

Posts: 10

Location: Middletown NY

|

Posted: Fri Nov 03, 2006 6:29 pm Post subject: Posted: Fri Nov 03, 2006 6:29 pm Post subject: |

|

|

I'll post some pics tomorrow. The camera batteries are dead and I can't find the charger. LOL

The pull down could be faster but the pump seems to do OK.

I don't have any problems with the plastic sealing sealing around the platen.

The "white cylinder" on the left is a 4' x 8' sheet of styrene rolled up.

The nichrome wire is direcly mounted to the board. I can't find the data sheet that came with the oven kit. |

|

| Back to top |

|

|

jegner

Site Admin

Joined: 30 May 2003

Posts: 2144

Location: Texas, USA

|

Posted: Fri Nov 03, 2006 7:09 pm Post subject: Posted: Fri Nov 03, 2006 7:09 pm Post subject: |

|

|

Well done, and good to see you here! Welcome to the board. I'm glad to see someone who had built the Hobby-Vac from Doug's plans post his experiences with his design.

Jim |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Sat Nov 04, 2006 5:21 am Post subject: Posted: Sat Nov 04, 2006 5:21 am Post subject: |

|

|

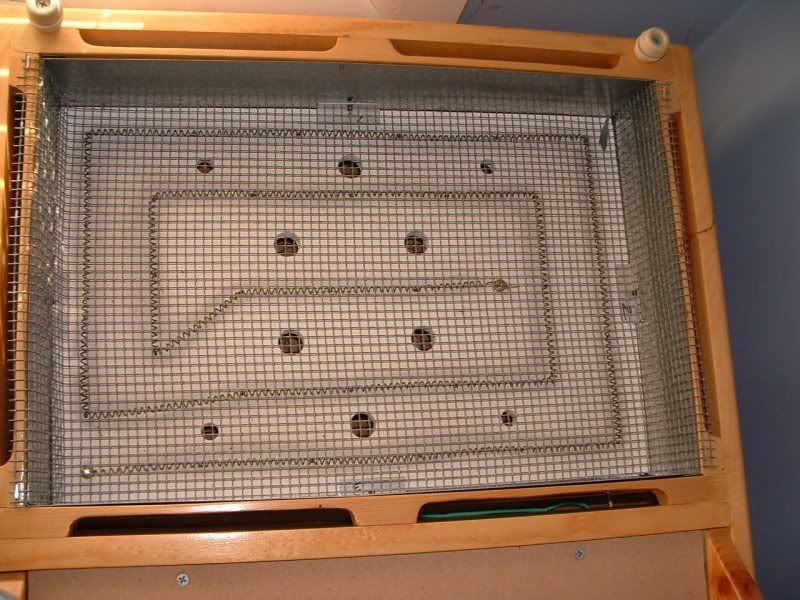

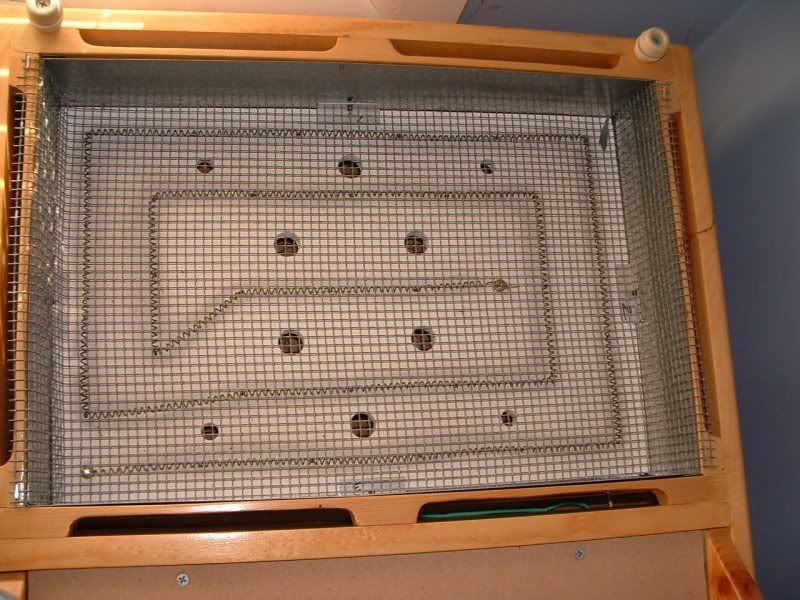

It looks like the oven has mesh (hardware cloth?) across the tops of the side walls.

That doesn't look like it leaves much room for sag, before the plastic would touch the mesh. How much sag can you get? |

|

| Back to top |

|

|

tallpaul

Newbie

Joined: 31 Oct 2006

Posts: 10

Location: Middletown NY

|

Posted: Sat Nov 04, 2006 9:13 am Post subject: Posted: Sat Nov 04, 2006 9:13 am Post subject: |

|

|

Here's a pic of the oven:

From the clamp frame to the hardware cloth is only 3" |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Sat Nov 04, 2006 10:47 am Post subject: Posted: Sat Nov 04, 2006 10:47 am Post subject: |

|

|

| Thanks; that helps a lot. From the other picture it looked like the hardware cloth went straight across the top. (Which would only give you about an inch for sag.) Now I can see that it goes straight across near the bottom, and comes up on the sides. That makes more sense. |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Sat Nov 04, 2006 10:24 pm Post subject: Posted: Sat Nov 04, 2006 10:24 pm Post subject: |

|

|

| Quote: | The pull down could be faster but the pump seems to do OK.

I don't have any problems with the plastic sealing sealing around the platen. |

I'd think a 10 CFM pump would do pretty well that size platen. That's a serious pump. (I just upgraded to a 2.5 CFM pump.)

If my calculations are right, Thurston James's plans give you something like 60 CFM for the pulldown, with a surge tank. Your forming area is about a third the size, and the bucks are probably about half that high, all other things being equal, so 1/6 of 60 CFM should be comparable. |

|

| Back to top |

|

|

|