|

www.TK560.com

Vacuum Forming, Movie Prop, Sci-fi and GIjOE Forum

|

|

|

| View previous topic :: View next topic |

| Author |

Message |

anakinjay

Newbie

Joined: 22 Dec 2006

Posts: 12

|

Posted: Wed Oct 31, 2007 2:32 pm Post subject: How hard is it to use MDF as molds? Posted: Wed Oct 31, 2007 2:32 pm Post subject: How hard is it to use MDF as molds? |

|

|

How hard is it to learn to sculpt MDF into molds? I'm fairly artistic... And I think I could easily get just the general shape down, but some of the finer details (the gap inbetween the chest, the hard angles... the details in the abs and edging).. etc... I just can't see that happening.

Can you guys who use MDF molds list the tools you use, and what they're used for? as in.. I use a planar for this part.. and when I need to do this, I use a band saw... whatev.. (I'm not a wood worker.. yet! hehe)

Also, could you go into some more detail on how you make the finer detail? I'd really appreciate it..

Thanks! |

|

| Back to top |

|

|

CJanssen

Expert

Joined: 17 Feb 2007

Posts: 215

Location: Beaverton OR

|

Posted: Wed Oct 31, 2007 8:00 pm Post subject: Posted: Wed Oct 31, 2007 8:00 pm Post subject: |

|

|

Except for all the dust, working with the mdf is alright. I start my molds by cutting the mdf sheets into the general shape of the mold with my table saw or band saw (depending on the shape)

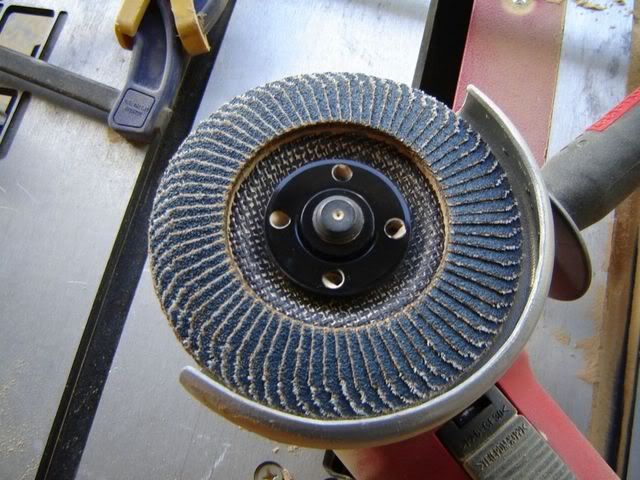

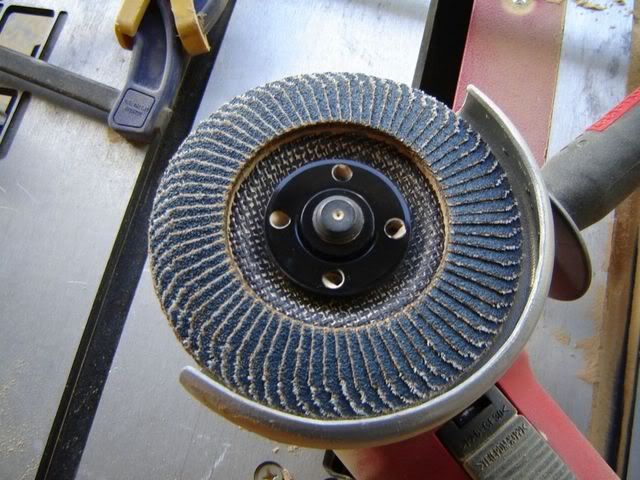

After gluing all the sheets together I do the forming with the planer and an agle grinder with this sanding head on it:

It works great at taking the mdf down

For the finer details, I use some small wood chisels, sandpaper, bondo. Also on some of the smaller areas I glued on other pieces of wood rather than trying to form the mdf. Heres an example with the ab mold.

I use my belt/disc sander ALOT on my molds as well, thats when the dust really starts to fly.

Hope that helps,

CJ

_________________

"What, you think your some kind of Jedi?" |

|

| Back to top |

|

|

anakinjay

Newbie

Joined: 22 Dec 2006

Posts: 12

|

Posted: Thu Nov 01, 2007 12:44 pm Post subject: Posted: Thu Nov 01, 2007 12:44 pm Post subject: |

|

|

In that picture above.. do you use bondo to fill in the gaps between the wood pieces? or did you form it right like that?

And yes, THANK YOU.. that helps a lot! |

|

| Back to top |

|

|

CJanssen

Expert

Joined: 17 Feb 2007

Posts: 215

Location: Beaverton OR

|

Posted: Thu Nov 01, 2007 5:38 pm Post subject: Posted: Thu Nov 01, 2007 5:38 pm Post subject: |

|

|

I used bondo to fill in all the gaps. Also, I pretty much bondo the entire mold, sand it smooth, and then spray it with primer.

Heres a pic of that mold finished. Well, it was finished until I started re-working it (its almost finished again)

Glad to help out

CJ

_________________

"What, you think your some kind of Jedi?" |

|

| Back to top |

|

|

TK 109

Guru

Joined: 11 May 2007

Posts: 712

Location: Galena, Ohio

|

Posted: Thu Nov 01, 2007 6:21 pm Post subject: Posted: Thu Nov 01, 2007 6:21 pm Post subject: |

|

|

nice work, cj

nice, sharp detailing!

could you post a pic of a pull one you vacuum-form it?

see, anakinjay, bondo can REALLY clean-up your molds. the wood that

cj, you've actually got chipboard on that codpiece, correct? does that stuff sand down faster than MDF? thanks!

here are some of my molds. i just use a beltsander mounted on my sawhorses to make a rather crude benchsanding jig. the paper is 50 grit, really cuts-up the MDF FAST. and then i apply the spot filler, and bond as needed.

this is the sholder bell armor, and it is painted-over with SPOT-FILLER PRIMER, grey. this mold is actually made of 2x6 pine, what i had on hand, and it cut-down on the amount of wood i had to use!

the CHEST. getting the shape of the pecs was interesting, i used the dremel tool with a cutting/engraving bit to to the rough shaving, and then used a griding wheel to do some detailing, and to level the lower "triangle", and then i PLASTERED that thing with bondo to smooth and contour it, paying close attention to the pecs. i still don't have it quite right!

here is a pull of the chest with haircell ABS, for reference (i guess...)

i hope that helps you man, good luck and most importantly BE SAFE and HAVE FUN!

_________________

-Alex

-------------------------------------------------------

|

|

| Back to top |

|

|

CJanssen

Expert

Joined: 17 Feb 2007

Posts: 215

Location: Beaverton OR

|

Posted: Thu Nov 01, 2007 7:21 pm Post subject: Posted: Thu Nov 01, 2007 7:21 pm Post subject: |

|

|

Heres the pic of the pull, went ok except for around the small boxes in the center lacking some detail. I will be making a mold to pull some add-on plates with the TK buttons.

I had forgotten that I didnt use mdf for that mold.... chipboard is close to mdf, but mdf is alot easier to sand.

CJ

_________________

"What, you think your some kind of Jedi?" |

|

| Back to top |

|

|

TK 109

Guru

Joined: 11 May 2007

Posts: 712

Location: Galena, Ohio

|

Posted: Fri Nov 02, 2007 7:26 am Post subject: Posted: Fri Nov 02, 2007 7:26 am Post subject: |

|

|

alright, was just wondering, thanks.

i don't even think that chipboard is even a cheaper option than MDF! i mean, not only is the stuff more expensive, but it doesn't sand down any easier.

ok thanks!

_________________

-Alex

-------------------------------------------------------

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|