|

www.TK560.com

Vacuum Forming, Movie Prop, Sci-fi and GIjOE Forum

|

|

|

| View previous topic :: View next topic |

| Author |

Message |

jegner

Site Admin

Joined: 30 May 2003

Posts: 2144

Location: Texas, USA

|

Posted: Thu Sep 28, 2006 2:33 pm Post subject: Posted: Thu Sep 28, 2006 2:33 pm Post subject: |

|

|

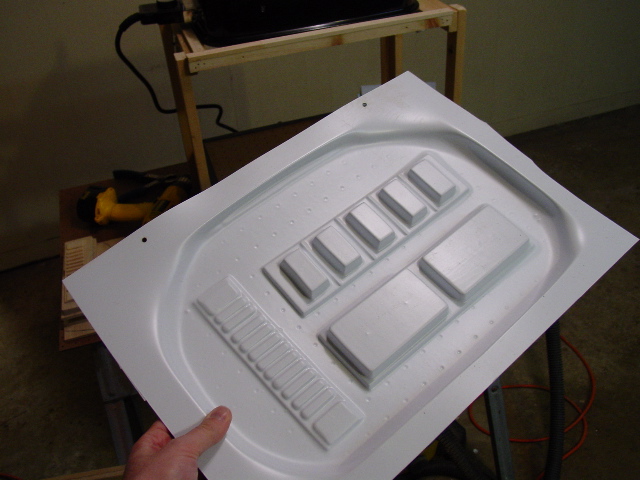

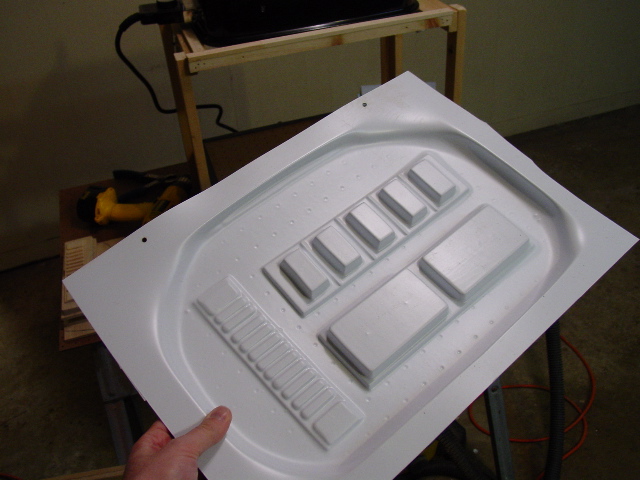

Here is my over/under using the sunbeam grill:

http://www.tk560.com/vactable2.html

It works but as you can see from this pic

The cold spots show up really well.

Great for small parts, though. |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Thu Sep 28, 2006 3:37 pm Post subject: Posted: Thu Sep 28, 2006 3:37 pm Post subject: |

|

|

| Quote: | | The cold spots show up really well. |

Yeah. I've been trying to interpret that picture.

I'm wondering if the wooden rails you have the grill resting on are blocking some of the infrared to the sides. It looks to me like the grill (housing) is too deep already, and will block a significant amount of IR.

(Not just direct IR, but IR reflected off the reflector behind the heating element. That indirect IR should be almost half the IR---the heating element radiates up and down equally, and an aluminum reflector should reflect over 90% of infrared.)

I think you were right to invert the reflector so that it reflects IR outward, rather than inward. Unfortunately, when you do that, even more of it just hits the housing wall (which is dark) and mostly gets wasted without spreading the heat as intended.

(That's especially true for reflected IR. From the point of view of the edge of the plastic, there should be a mirror image of the outermost heating element in the reflector, behind the actual heating element, and visible between the edge of the housing and the direct image of that element. Unfortunately, that image gets blocked by the housing further in from the edge than the direct image. That's bad because that reflection should be providing almost as much heat as the direct path.)

It looks like the rounded corners on the grill housing are a problem, too, blocking even more reflected IR than on the sides and ends.

To do a really good job with this heating element, I think I'd have to build a new housing, a little longer and wider, and with square corners. Past the heating elements, the sides should angle down around 45 degrees to reflect most of the IR down to the plastic. (Most of the IR hitting that part of the reflector would be traveling almost horizontally, so a 45 degree angle would send it down to the plastic once it gets past the footprint of the heating element.)

| Code: |

/-------\

/ * * * * \

|

(That's ASCII art, not code, and I'm pretending that the pair of slashes on each end makes one 45-degree side. The asterisks are the long parts of the heating element, viewed in cross section.)

That still wouldn't make it heat really evenly---the middle is still going to be hotter. Another step would be to put a reflector under the middle part of the heating element, reflecting some of the IR toward the edges, so that it either directly hits the plastic near the edge, or reflects again off the 45-degree bits around the edges.

| Code: |

/-------\

/ * * * * \

/ / \ \

|

That seems like a lot of fussing to salvage a heating element, so I'm thinking of just wiring up a little nichrome coil heater with a better distribution to start with.  |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Fri Sep 29, 2006 1:48 am Post subject: Posted: Fri Sep 29, 2006 1:48 am Post subject: |

|

|

Jim,

Did you bypass the thermostat on the Sunbeam, like Ralis Kahn did?

If not, that may be part of why it didn't heat well when you put aluminum between the elements and the plastic.

I've been fiddling with my Sunbeam and I think I've gotten it to heat more evenly. I put a diamond-shaped piece of perforated aluminum (from a disposable grill topper) over the middle of it, leaving the corners fully exposed. (I also left the slanted edge of the grill topper on, bending it a little more to use it as a 45 degree reflector around the edges.)

This seems to redirect some of the IR to the corners. (Basically, most of the IR bounces around between the backside reflector and this frontside perforated reflector, until it either comes out a hole, makes its way to an uncovered corner area, or is absorbed.)

The perforated aluminum is about 1/3 holes, and that seems to be roughly the right ratio---letting enough IR through in the middle diamond, and redirecting a fair bit toward the corner triangles, too. |

|

| Back to top |

|

|

crashmann

Guru

Joined: 27 Sep 2005

Posts: 501

|

Posted: Fri Sep 29, 2006 7:35 am Post subject: Posted: Fri Sep 29, 2006 7:35 am Post subject: |

|

|

| drcrash wrote: | Jim,

Did you bypass the thermostat on the Sunbeam, like Ralis Kahn did? |

I opened up the thermostat control, and put a zip tie around the contacts so it always stays connected. I'll post the picture a little later.

I'm having trouble with the Sunbeam grill not heating the corners of the plastic. My friend was a little ambitious when he chose the large cookie sheet for the platen, and it extends a few inches too far compared to the Sunbeam grill.

I'm intrigued by your diamond shaped piece of aluminum. Can you post a picture of what you've created?

Thanks!

Charlie

TI-386 |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

|

| Back to top |

|

|

jegner

Site Admin

Joined: 30 May 2003

Posts: 2144

Location: Texas, USA

|

Posted: Sun Oct 01, 2006 12:38 pm Post subject: Posted: Sun Oct 01, 2006 12:38 pm Post subject: |

|

|

A few things I noticed with the Sunbeam grill vac table. First, the heating element does not heat even at all. The center is much hotter than the edges. I used all sorts of tricks to get those corners hot, and nothing worked. About the best I could do was to bend some strips of sheet metal, around the element, and use that as a sort of extension to the element. The element is very round, and is not intended for this sort of application. I even went so far as to make a refractory mix of Perlite, and furnace cement, and coated the bottom of the black grill base, to no positive effect.

The grill actually sits on a tiny bit of a shelf made from aluminum strips, so NONE of the direct heat is lost due to the mounting frame. I wanted to be sure it would not burn my frame. LOL.

The thermostat kept shutting off right when I needed it to keep going. A rewire of that would be nice, but it defeats the ability to regulate the temp if I did. So that was never done.

The best you can hope for, IMHO with one of these grills is a small 8.5x11 size useable forming area. Good for scale models, and small parts like TOS communicator bodies, or tricorder parts, but not great for trooper armor.

Jim |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Mon Oct 02, 2006 10:11 am Post subject: Posted: Mon Oct 02, 2006 10:11 am Post subject: |

|

|

Jim,

I think pretty much any infrared heater should be able to heat pretty much any flat surface evenly, with the right reflector. The main trick is to reflect the IR to the plastic, rather than absorbing it. You shouldn't need a refractory coating, and it's probably counterproductive.

With a solid sheet of aluminum, the problem is that the IR must be absorbed by the aluminum and re-radiated or convected from the other side. Most of the IR will not be absorbed by the aluminum---it will be reflected and absorbed by the refractory coating on the other side of the heating elements. (And half of the re-radiated heat from the aluminum will go the wrong way, and mostly be absorbed by the refractory lining, too.) You'll heat the oven itself way more than you heat the aluminum or the plastic.

I think what you were doing would eventually work, with the right tweaks, but would be harder than building the right reflector to direct the IR to the plastic before it's absorbed.

As for the thermostat... I'd like to have a thermostat, too. I'm afraid the Sunbeam thermostat isn't very good, though. I used a grill thermometer and noticed the temperature inside the grill housing fluctuating by dozens of degrees in an on/off cycle. (Usually about 30 degrees, I think, but sometimes 40.) It may be better to control the heat manually, one way or another.

In your setup with the aluminum sheet, I'd think the thermostat would be a killer. Since the IR is mostly being absorbed by the rest of the oven, not the aluminum, the whole oven needs to get very hot before lots of IR starts re-radiating from the front side of the aluminum and heating the plastic. (And you'd need to insulate the rest of the oven really well, so that most of the heat comes off the aluminum rather than being re-radiated or convected from the rest of the oven.) The thermostat will keep that from ever happening.

Paul |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Wed Oct 04, 2006 9:01 pm Post subject: reflector works w/Sunbeam grill over-and-under Posted: Wed Oct 04, 2006 9:01 pm Post subject: reflector works w/Sunbeam grill over-and-under |

|

|

I did some tests, and the diamond-shaped reflector made out of a disposable grill topper works pretty well.

The heat is much more even---no big hot spot in the middle. I can tell this just from the red glow from the heating element, both visually and by putting my hand under it and feeling that it's pretty even.

It also shows up in the pulls. I did some pulls with a test plug, and now the plastic isn't annoyingly thin in the middle, and there's better detail further out. (The very cornerest corners are still a bit lame, but most of the 12' x 18" area seems quite usable.)

There are still a couple of hot spots about a third of the way from the end of the oven (not in the middle) which I want to tone down and try to get the heat into the corners. I probably should have made the diamond thing extend another inch or so toward the end with the two rounded bits, i.e., away from the plug/thermostat end.

Unfortunately, when I went back to the dollar store to get another pair of grill toppers to mess with, they didn't have them any more. I'm guessing they're a seasonal item. (There were plenty of turkey-roasting pans all the sudden.)

The heating element in my sunbeam seems to heat asymmetrically. One of the long sides is simply brighter/hotter than the other. I'll try to fix that with an asymmetrical reflector.

I'm thinking that to get a really good heat distribution, I'm going to need a skirt/shroud thing like Harley Guy's. That will let me put the plastic further from the heating element, where the IR illumination is more even, without much efficiency loss. It should also reduce convective cooling of the corners. |

|

| Back to top |

|

|

drcrash

Guru

Joined: 04 Sep 2006

Posts: 705

Location: Austin, Texas

|

Posted: Wed Oct 04, 2006 9:05 pm Post subject: Posted: Wed Oct 04, 2006 9:05 pm Post subject: |

|

|

By the way, once I got my Sunbeam inverted, I realized that the heating element wouldn't be recessed as far as I thought into the housing---so the edges of the housing block less of the IR than I thought, and it can illuminate/heat a bigger area.

I still think it could use better 45-degree reflectors around the edges than my grill topper hack is doing. (They don't go all the way to the back reflector, so a significant amount of IR goes right over them to the housing wall, rather than being reflected down to the plastic around the edges. That can't be good.) |

|

| Back to top |

|

|

harley guy

Novice

Joined: 25 Nov 2005

Posts: 71

|

Posted: Fri May 11, 2007 10:34 pm Post subject: Posted: Fri May 11, 2007 10:34 pm Post subject: |

|

|

| here is the info boxjoint |

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|