CONTENTS:

TK560 Main

Star

Trek TOS Props |

Communicators

Phasers

Tricorders

Star

Wars EP IV-VI Props |

Helmets

Blasters

Stormtrooper Armor

Rebel Fleet Trooper

Lightsabers

Astro-Mech Droids

How-to Guides

Vacuform Table

Misc.

Sci-Fi Props |

Cylon

Centurion

Viper Pilot Helmet

M41-a Pulse Rifle

Motion Tracker

B5 PPG

Prop Photo Gallery

1964-1976

GIjOE Figures |

Retro

Box Designs

Repair/Restoration

Replica Parts

40th Anniversary

World

War II Militaria |

Replica

Weapons/Gear

Reenactment Units

ME262 Project

Civilian

Marksmanship Program |

M1

Garand Rifle

M1903 Springfield

Rifle

M1 Carbine

Other

Stuff |

Discussion

Board

Lauren Photo Albums

David's

Photo Album

Egner II Design

Fan Film Project

The Mac Plus Project

Catalog

Page

Please note, that the images, logos, and respected artworks, are property of the original copyright owners. TK560 has no affiliation with any of the intellectual property owners. This is a fan site dealing with movie and television replica props, original GIjOE action figures, World War II memorabilia, and marksmanship/ firearms interests. Most of the images used on this site are photographed by the site owners. Official logos are used to identify specific products/ manufacturers.

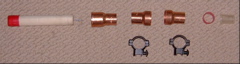

| Here is a break-a-part view of the blaster prior to painting. Here is the break-a-part view of the scope

The parts for the trigger and the nozzle. Sub assembly The blaster still under construciton. Final assembly prior to painting.

|

This is Luke Warmwater's version of the Rebel Fleet Soldier's DH17 Blaster. Based on the Sterling L2A3 machine gun with lots of modifications to the barrel and magazine, this blaster is first seen in the opening sequences of Star Wars.This tutorial includes the basic instruction for constructing your own version from common hardware store parts, including the "aimpoint scope". Some of the parts like the endcap and pistol grip are resin castings from a real gun, but these parts are easily made from plywood, and PVC endcaps. Use your creativity and make your own version! Its easy, and here's how. Here is the breakdown: Blaster body fabricaton Parts: Procedure: Here is the breakdown for the Scope fabrication Parts: Made the scope out of copper plumbing parts with a 3/4 inch wooden dowel inside to hold it together. The clear tip is a cap from a chick-grooming product. The scope mounts are from Bass Pro. The two red caps I found. I cut one of them to make the ring in the front. This ring holds the clear cap on. I drove a nail into the dowel front which will be the orange sight when painted. The scope rings are standard stuff I found at Bass Pro. Final thoughts A conduit mount is the metal piece near the endcap. A brass hook, filed down, is the trigger. I've cut out the mag well and used chrome tape on the inner bolt. I also dremeled the spiral grooves in the bolt. I've also glued plasitc sheeting [garage sale sign] onto the plywood.

Here is a price list. Obey Wannn's trip to both HD and Lowes. Here goes:

I got the resin

grips and endcap [available here]

$10-20 plus shipping.

Painting tips: For painting I used a rustoleum textured paint in black for the main body and a mettalic silver paint for the nozzle. The silver paint was problematic, while looking like metal it is not as silvery as I had hoped. If I had to do it over again I would use a hobby-type silver paint instead of rustoleum. Weathering: Final Thoughts:

|

| Obey Wann's hardware store images: |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is a view of the progress done so far with the supplies purchased from the hardware store. |

Here is a view of each part. |

|

|

|

|

|

|

Be sure to check out the Rebel Fleet Trooper Costume page for additional information.

Here is a link for converting one of the Hasbro Nerf DH-17 Blasters